直进式拉丝机

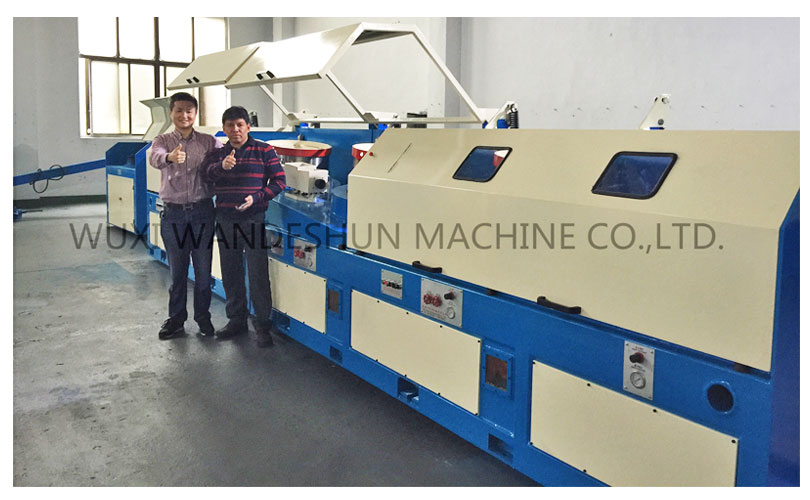

Our straight line drawing machine applies advanced international technology, with digestion and absorption, the drawing machine is applicable for high intensity and performance demand. It mainly applied for the production of steel curtain wire, tyre steel wire, steel wire for rope, spring steel wire, stainless steel wire, gas welding wire, arc welding wire, etc. The capstan diameter of the series products is φ350-φ1200mm with maximum inlet diameter of φ14mm and minimum outlet diameter of 0.7mm.

The equipment line drawing machine contains the function of human-machine dialogue, over-temperature protection for motor, alarm for abnormal water pressure, fault display, etc. Its transmission structure is plane double enveloping worm wheel+ narrow V band with low noise. The capstan applies the combination of narrow water cooling and air cooling with good cooling effect. AC variable-frequency and Siemens PLC is used for speed adjustment. Generally, it is an kind of efficient and advanced drawing machine equipment with easy operation, high degree of automation and broad process scope.

| Items | Unit | LZ9-12/1200 | LZ10/800 | LZ9/700 | LZ10/560 | LZ10/400 |

|---|---|---|---|---|---|---|

| Diameter of capstan | mm | 1200-900 | 800 | 700 | 560(600) | 400(500) |

| Drawing dies | time | 9-12 | 10 | 9 | 10 | 10 |

| Max diameter of inlet wire | mm | φ14-18 | φ10-8 | φ8-6.5 | φ6.5-5.5 | φ3.5-2.5 |

| Min diameter of outlet wire | Mm | φ5-3 | φ4-2.5 | φ3-2.5 | φ2-1.8 | φ1.1-0.8 |

| Drawing line speed | m/min | 300 | 360 | 480 | 720 | 840 |

| Loading capacity | Mpa | ≤1300 | ≤1300 | ≤1300 | ≤1300 | ≤1300 |

| Total compression rate | % | 87.24-92.89 | 90.53-90.23 | 85.94-85.21 | 90.53-89.29 | 90.12 |

| Average compression rate | % | 20.45-19.58 | 21.00-20.75 | 19.58-19.13 | 21.00-20.02 | 20.5 |

| Motor power | Kw | 110-90 | 90-55 | 75-55 | 37-22 | 15-7.5 |